Deck Screws

A deck must withstand the harshest environmental conditions, so deck screws are manufactured to accommodate this application. Most high quality deck screws are made of stainless steel or another material which is resistant to corrosion. Deck screws are designed so they are easy to drive into decking planks.

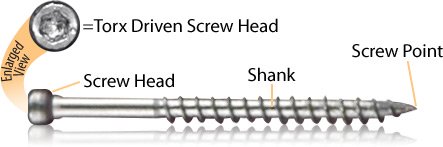

Just like standard screws, deck screws also come in a wide variety of lengths and widths, which are commonly called shanks. Deck screws feature different driver shapes on the screw head. A popular driver type on deck screws is in the shape of a square. The square shape holds the driver better and it does not strip out as easy as a Phillips head screw.

Deck screws usually have a sharp, narrow point on them to reduce the necessity of drilling pilot holes (Dense decking materials such a Ipe, Tigerwood & other exotic hardwood typically requires the decking to be predrilled before screws can be fastened. Some composite decking also requires predrilling of pilot holes. **Check with the installation instructions of the particular decking you are installing to determine whether or not drilling pilot holes is necessary.) On softer decking material, such a cedar, “self tapping” deck screws can be fastened without drilling pilot holes.

Ultimately the most important aspect of a deck screw is it’s resistance to corrosion. This is because no matter how easy the screw is to install it need to maintain it strength over the life of the deck. If a low quality deck screw is installed it will not provide the hold down power over the lifespan of the deck. If the deck screw loses its strength the deck boards will begin to pull away from the floor joists.